MAN Diesel has recently announced a further extension to its line-up of large bore, four-stroke gas engines. The following passages come from Man Diesel's 02/2009 edition of DieselFacts.

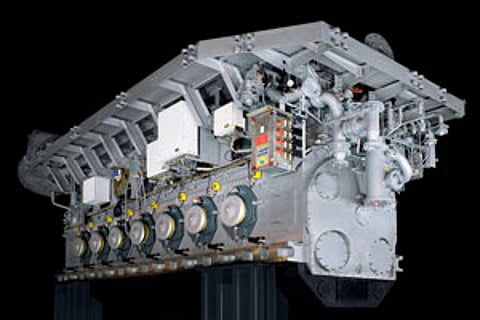

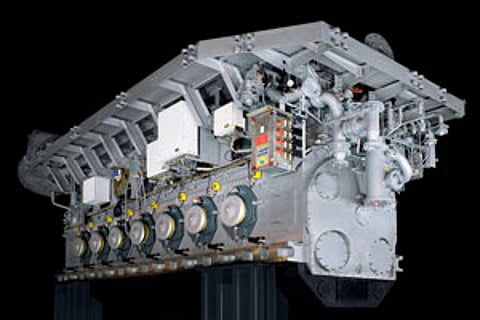

The new engine is the 51/60G, which like its 51/60DF dual-fuel stable mate is derived from MAN Diesel's type 48/60 diesel-engine platform. The new engine uses a distillate fuel pilot injection system to achieve reliable, stable ignition of lean air:gas mixtures in a large-bore, open combustion chamber.

As a result, the new gas engine has one of the highest power densities in the four stroke gas engine field as well as low emissions of oxides of nitrogen (NOx) and high fuel efficiency. This choice of gas ignition technology also alleviates one of the main weaknesses of spark-ignited gas engines, namely the relatively short exchange intervals of even the best spark plugs.

By contrast, the liquid-fuel pilot ignition system of the 51/60G gas engine exhibits the considerably longer service intervals typical of diesel engine fuel-injection equipment.

Other advantages include low gas admission pressures, high and stable ratings in hot and high power plant locations and excellent load imposition, and load following characteristics.

"The 51/60G is now the largest, most powerful medium-speed gas engine on the market," said Dr Stephan Mey, Head of MAN Diesel's Augsburg-based Power Plant business unit. "In particular, with the 51/60G, we are aiming to bring the typical virtues of gas engines to power and cogeneration plants with electrical outputs in the range 100 to 300MW class. These benefits include intrinsically clean combustion of gases containing methane combined with high fuel efficiencies and hence low emissions of carbon dioxide.

Versions

In detail, the 51/60G is offered in a nine-cylinder inline version and vee-configuration versions with twelve, 14 and 18 cylinders. Standard rated outputs are 1,000kW per cylinder for 60Hz power generation and 975kW per cylinder for 50Hz power generation. This overall power range from 8,775kW to 18,000kW mechanical equates to nominal generator set outputs of 8,538kW to 17,514kW electrical.

Advanced fuel/ignition control

The 51/60G makes extensive use of microprocessor control technology to achieve its favourable economics and low emissions.

Gas admission is precisely controlled via electronically controlled, electrically actuated valves in the 51/60G's inlet ports, while pilot fuel injection is likewise via an electronically controlled, electrically actuated common-rail system.

Common-rail injection technology allows flexible setting of injection timing, duration and pressure for each cylinder. This capability ensures the reliable ignition of lean air: fuel mixtures, precise balancing of cylinder outputs and – essential for a gas engine – rapid response to combustion knock signals on a cylinder-by-cylinder basis. The pilot fuel quantity represents about 0.8 percent of he energy required to achieve the 51/60G engine's standard outputs, contributing to the engine's excellent NOx emissions.

Variable turbocharging

Further enhancing both control of the air: fuel ratio and the favourable efficiency of the 51/60G is the use of MAN Diesel's VTA Variable Turbine Area turbocharger technology.

On the 51/60G, the VTA system replaces the traditional method of air: fuel ratio control based on charge air bypassing. Where a bypass system dissipates energy by expelling excess charge air to the atmosphere, the VTA system uses variable nozzle rang vanes ahead of the turbocharger turbine to precisely match the charge-air output of the compressor to the engine's demand for combustion air.

As with gas admission and pilot fuel injection, the VTA system is electronically controlled.

Fuel consumption/emissions

On the fuel efficiency side, the overall effect of these measures is specific consumption for natural gas plus the liquid fuel pilot of 7,708 kJ/kWhe (7,500 kJ/kWhm) for generator sets powered by the 51/60G in NOx-optimised applications and 7,430 kJ/kWhe (7,230 kJ/kWhm) in efficiency optimised applications. On the exhaust emissions side, NOx levels below 500mg/m3 at five percent dioxide mean the 51/60G readily achieves both compliance with the limits prescribed in Germany's TA luft clean air code and undercuts the limits currently required by the World Bank by a wide margin.

Energy recovery

"Naturally, we expect the 51/60G to be popular in cogeneration and tri-generation application," Mr Mey noted. "In these plants, thermal energy recovered from engine sources in used for heating, cooling or generating process steam, resulting in energy utilisation levels as high as 95 percent.

As with out large diesel engines, a further energy recovery option on other from MAN Diesel with the 51/60G is a combined cycle set up in which the exhaust heat of the 51/60G engine is used to produce steam to drive a steam turbine generator.

In this way, the overall electrical output and efficiency of the power plant can be increase by ten to 15 percent without additional fuel costs"

For further information contact: