The US Navy has conducted the first shipboard test of the Multifunctional Automated Repair System (MARS), a portable robotic system that is capable of performing multiple repair operations including paint removal, grinding, ultrasonic inspections, and cold spray works.

Developed and built by Pennsylvania State University's Applied Research Laboratory (Penn State ARL), the MARS platform is designed to be easily adaptable with multiple repair end effectors and allows the user to easily execute normal ship repair tasks with minimal training.

The system is being vetted for its viability within a shipyard but also for use in an expeditionary or forward deployed environment.

Penn State ARL approached Norfolk Naval Shipyard (NNSY) to coordinate an opportunity to demonstrate MARS on an actual ship after a successful demonstration of the system at NSWC Port Humene Division (NSWC PHD). Unique from the previous demonstration, this evolution would be the first time testing shipboard cold spray for the navy using a newly developed hatchable cold spray system.

Currently NNSY is only performing cold spray repairs for ship components that are capable of being brought to its on-site cold spray facility.

The NNSY team and Penn State ARL chose a test location on ex-USS McKee, a decommissioned submarine tender. The ship had specific features to allow testing of the MARS upgrades as well as the cold spray repair system.

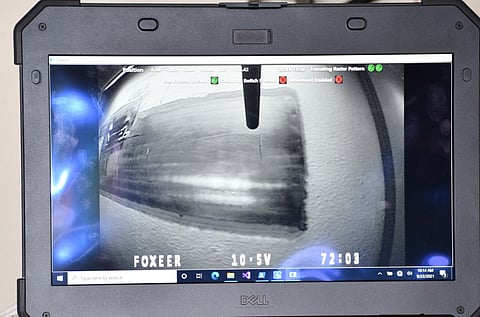

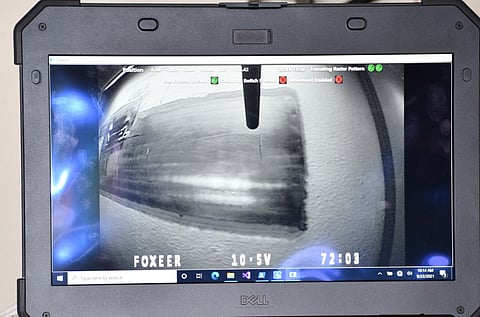

During the week-long demo, the team was able to test out MARS' ability to cold spray, grind, plasma blast and ultrasonically test various components. Sailors from the aircraft carrier USS George H. W. Bush were invited to take part in the demo to get hands-on experience working with the system and its controls to provide feedback to the team.

There will be more testing and demonstrations in the future after Penn State ARL performs additional modifications to the MARS system and is ready to field the system.

NNSY is gearing up for a hatchable cold spray system slated for arrival in early 2022.